Product Description

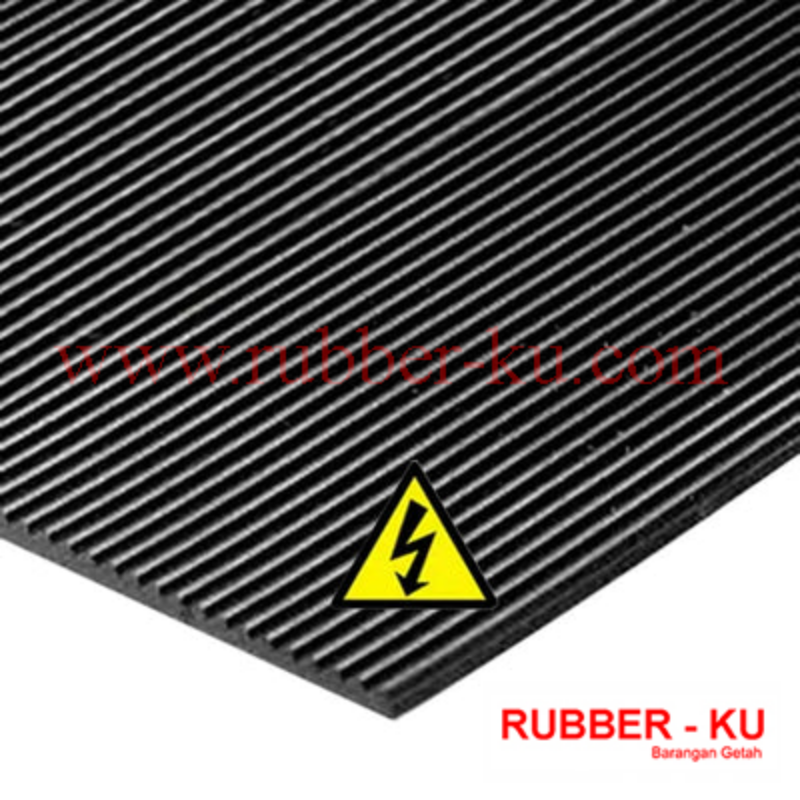

Insulating Rubber Mats | Electrical Rubber Mats | Corrugated Mat | Fine Ribbed Mats

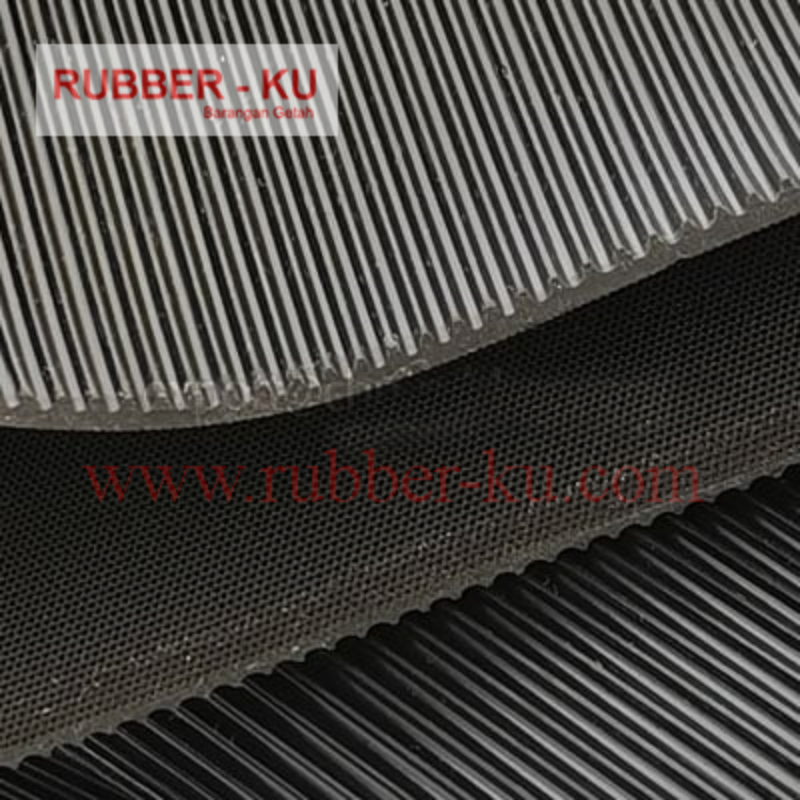

RUBBER-KU Electrical Insulation Rubber Mats available as per IEC 61111 standard and are highly electrical resistant. These Insulating Rubber Mats protect from the mortal shock generated from high voltage equipment’s, specially designed with anti-skid texture on top and bottom surface, it is leakage and Water proof, Fire, Oil & Acid resistant, supplied with Test Certificate

Insulating Rubber Mats, IEC 61111, Class 0

Anti-skid, Fine Ribbed (Corrugated) on Top & Textured Bottom

Working Voltage: 1,000 V (1000V)

Test Voltage: 5,000V

Breakdown Voltage: 10,000V

Size: 3.0mm thick x 1Mtr wide x 10Mtr length.

With Test Certificate

Insulating Rubber Mats, IEC 61111, Class 1

Anti-skid, Fine Ribbed (Corrugated) on Top & Textured Bottom

Working Voltage: 7,500V (7.5KV)

Test Voltage: 10,000V

Breakdown Voltage: 20,000V

Size: 5.0mm thick x 1Mtr wide x 10Mtr length.

With Test Certificate

Insulating Rubber Mats, IEC 61111, Class 2

Anti-skid, Fine Ribbed (Corrugated) on Top & Textured Bottom

Working Voltage: 17,000V (17KV)

Test Voltage: 20,000V

Breakdown Voltage: 30,000V

Size: 5.0mm thick x 1Mtr wide x 10Mtr length.

With Test Certificate

Insulating Rubber Mats, IEC 61111, Class 3

Anti-skid, Fine Ribbed (Corrugated) on Top & Textured Bottom

Working Voltage: 26,500V (26.5KV)

Test Voltage: 30,000V

Breakdown Voltage: 40,000V

Size: 6.0mm thick x 1Mtr wide x 10Mtr length.

With Test Certificate

Insulating Rubber Mats, IEC 61111, Class 4

Anti-skid, Fine Ribbed (Corrugated) on Top & Textured Bottom

Working Voltage: 36,000V (36KV)

Test Voltage: 40,000V

Breakdown Voltage: 50,000V

Size: 6.0mm thick x 1Mtr wide x 10Mtr length.

With Test Certificate

Making a purchase of the rubber mats for electrical purpose is simply the first step that you should take towards keeping your industrial premises safe. Not just for your employees but also your electrical assets and equipment. Although you might have heard that these mats last forever, it completely depends upon the way they are maintained.

All these aspects fall under the category of post-purchase details of the insulation mats. Although this does not involve anything that is complex or difficult, it is simply a process that guides you through the process that is to be followed afterwards.

Insulating Mats - Post Purchase Guide

One major reason that causes accidents at industrial places even when the mats are involved is irregular checking, testing and maintenance of these insulating mats for electrical purposes. People often get these mats installed and forget getting them checked on regular intervals.

Moreover, although these mats last long, they still have a deadline after which the effect of these mats starts reducing and thus the level of protection they provide too starts diminishing.

Generally, make it a rule to get your mats tested at least once in a year. The government too issues notices where they give instructions related to the mats that are allowed to be used at the industrial premises. So keep a check on these and if the mats you have fall out of the list, get them replaced.

The Cleanliness of the mats is another factor that can affect the life of these mats. If you have a setup where liquids spill on the mats or people walk over them with dirty shoes, then you need to get them cleaned.

This sort of non-maintenance can cause a lot of damage to the mats and thus affect their capacity. If you do not have mats that are permanently installed, make sure you get the mats cleaned and then keep them in some dry place.

Contact Details

Insulating Rubber Mats | Electrical Rubber Mats | Corrugated Mat | Fine Ribbed Mats

| Supplier | : | RUBBER-KU RUBBER PRODUCTS |

| : | rubberku@gmail.com | |

| Phone | : | +603 5191 7961 |

| Fax | : | +603 5191 5961 |

| Location | : | Selangor, Malaysia |

Enquiry Box

Other Products

Loading...Please Wait.

Loading...Please Wait.