Rubber Flexible Joint Installation Guide | How to Install Rubber Flexible Joint

Rubber Flexible Joint Installation Guide and How to Install Rubber Flexible Joint

Single Bellow Flexible Joint

Service and Conditions:

Make sure the expansion joint rating for temperature, pressure, vacuum, movements and selection of elastomer materials match the system requirements. Contact Twin City Hose if the system requirements exceed those of the expansion joint selected.

Vacuum Service for Spherical Rubber Connectors:

Vacuum rating is based on neutral installed length, without external load. These products should not be installed “extended” on vacuum applications.

Alignment:

Expansion joints are not designed to make up for piping misalignment errors. Pipe misalignment should be no more than 1/8” in any direction. Misalignment of an expansion joint will reduce the rated movements and can induce severe stress of the material properties, thus causing

reduced service life.

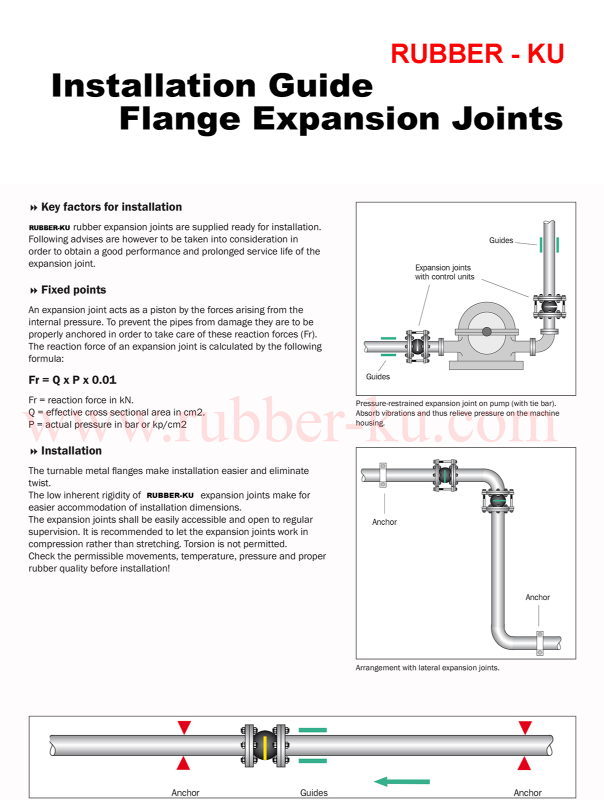

Anchoring:

Anchors are required whenever a piping system changes direction. Expansion joints should be located as close as possible to the anchor points. If an anchoring system is not used, it is recommended that control rods be installed on the expansion joint to prevent excessive movements from occurring due

to pressure thrust of the line.

Pipe Support:

Piping must be supported so the expansion joints do not carry any pipe weight.

Mating Flanges:

1. Install the expansion joint against the mating pipe flanges and install bolts so that the bolt head

is against the expansion joint flange. Flange to flange dimensions of the expansion joint must match the breech opening.

2. A spherical rubber connector must be compressed 1/8” to 3/16” during installation in order to obtain a correctly installed face to face dimension.

3. Make sure mating flanges are clean and are flat faced type. When attaching beaded end flange expansion joints to raised face flanges, ring gaskets are required to prevent metal flange faces from cutting the rubber bead during installation.

4. Never install expansion joints next to wafer type check valves or butterfly valves. Serious damage to the rubber flange bead can result due to the lack of flange mating surface and or bolt connection.